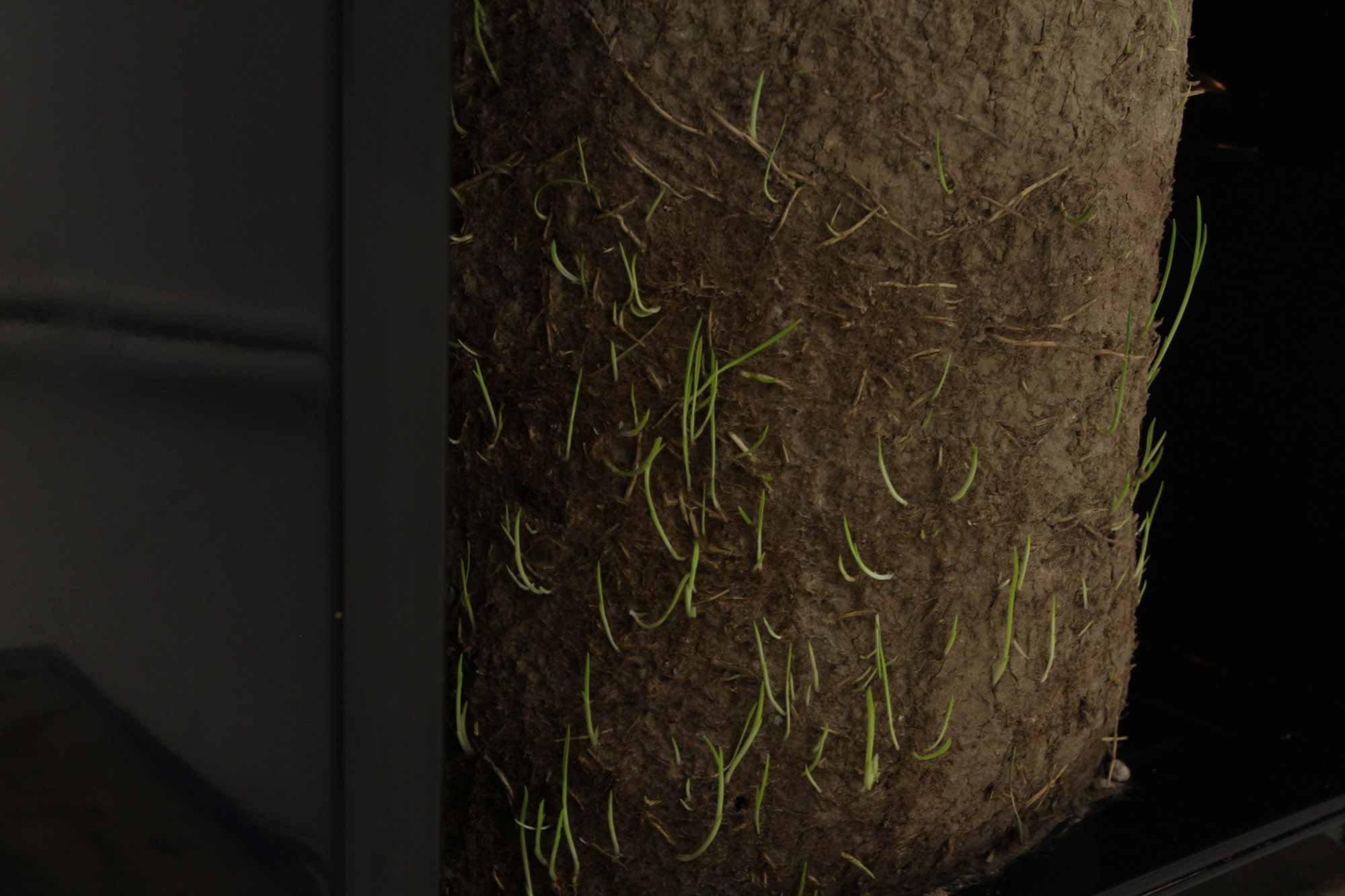

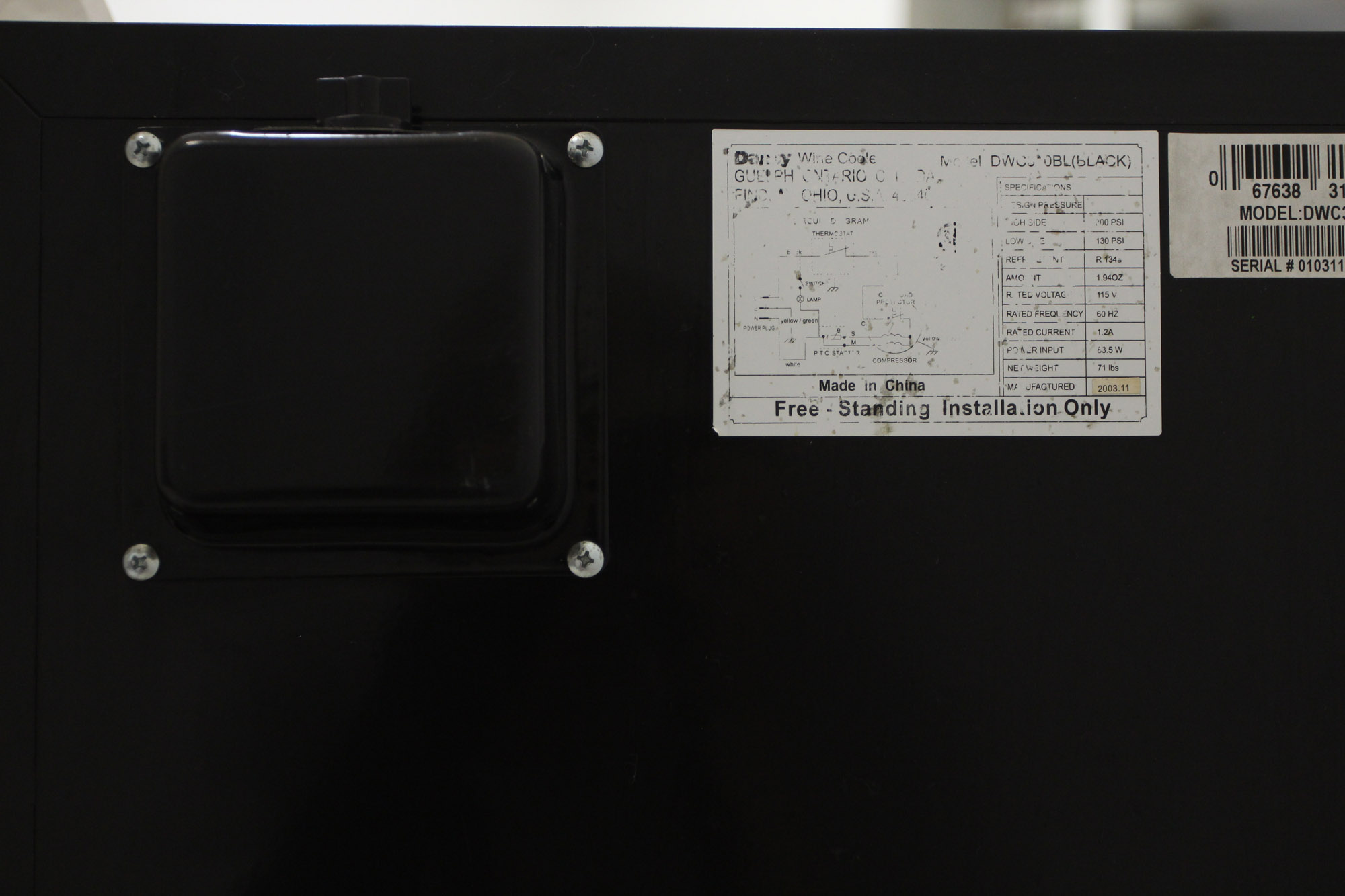

"Around 55 degrees (best way)" -

wooden pallet, wine cooler, sod, coconut growing medium, Perlite, 2015.

"Size 12 (before business)" - urethane resin, alginate, 2015.

"I swear to god he closed the merger because of his shoes" -

leather shoe, rubble, threaded rod, nut, twigs, sand, clamp on light fixture, grow bulb, 2015.

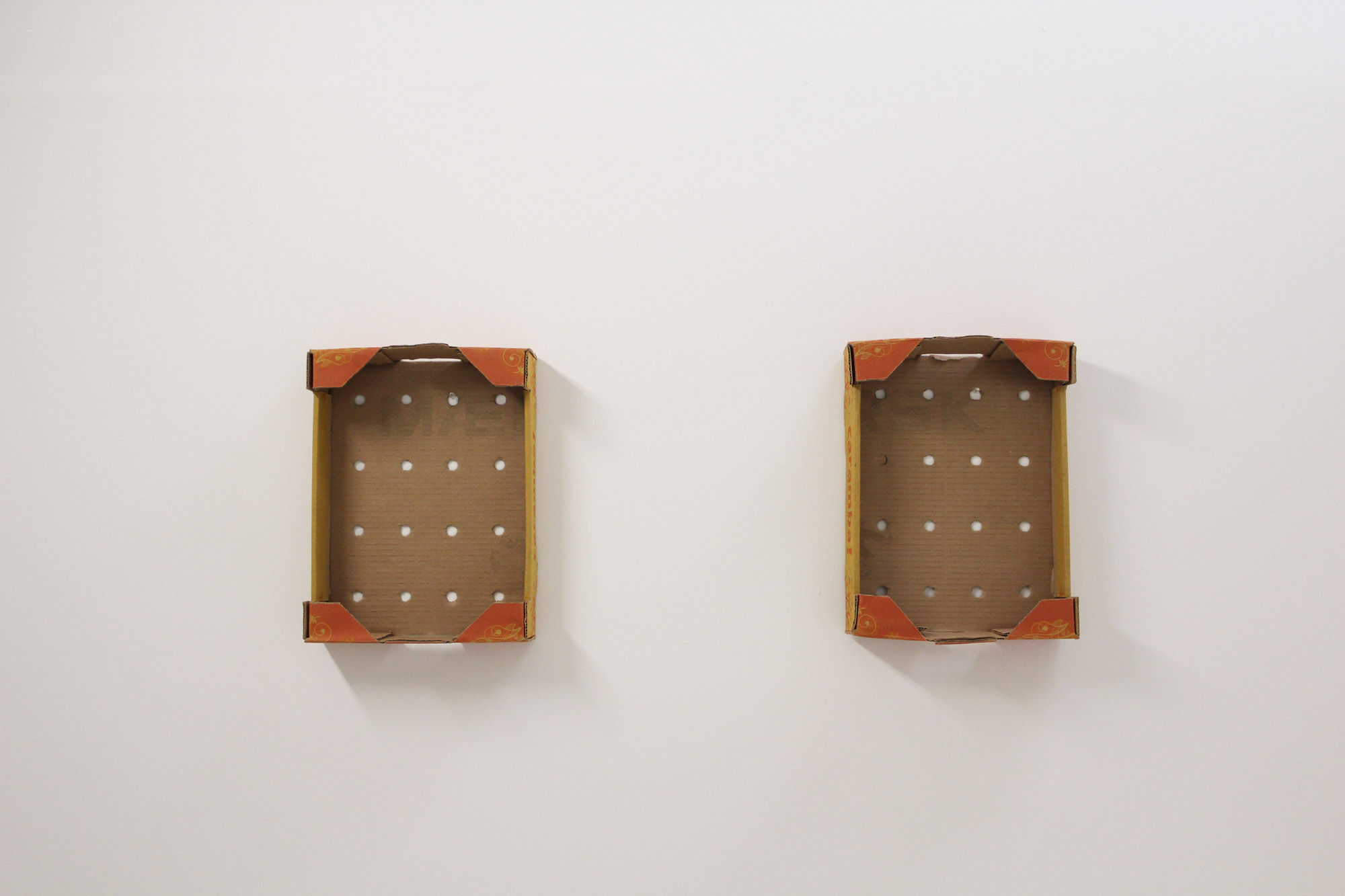

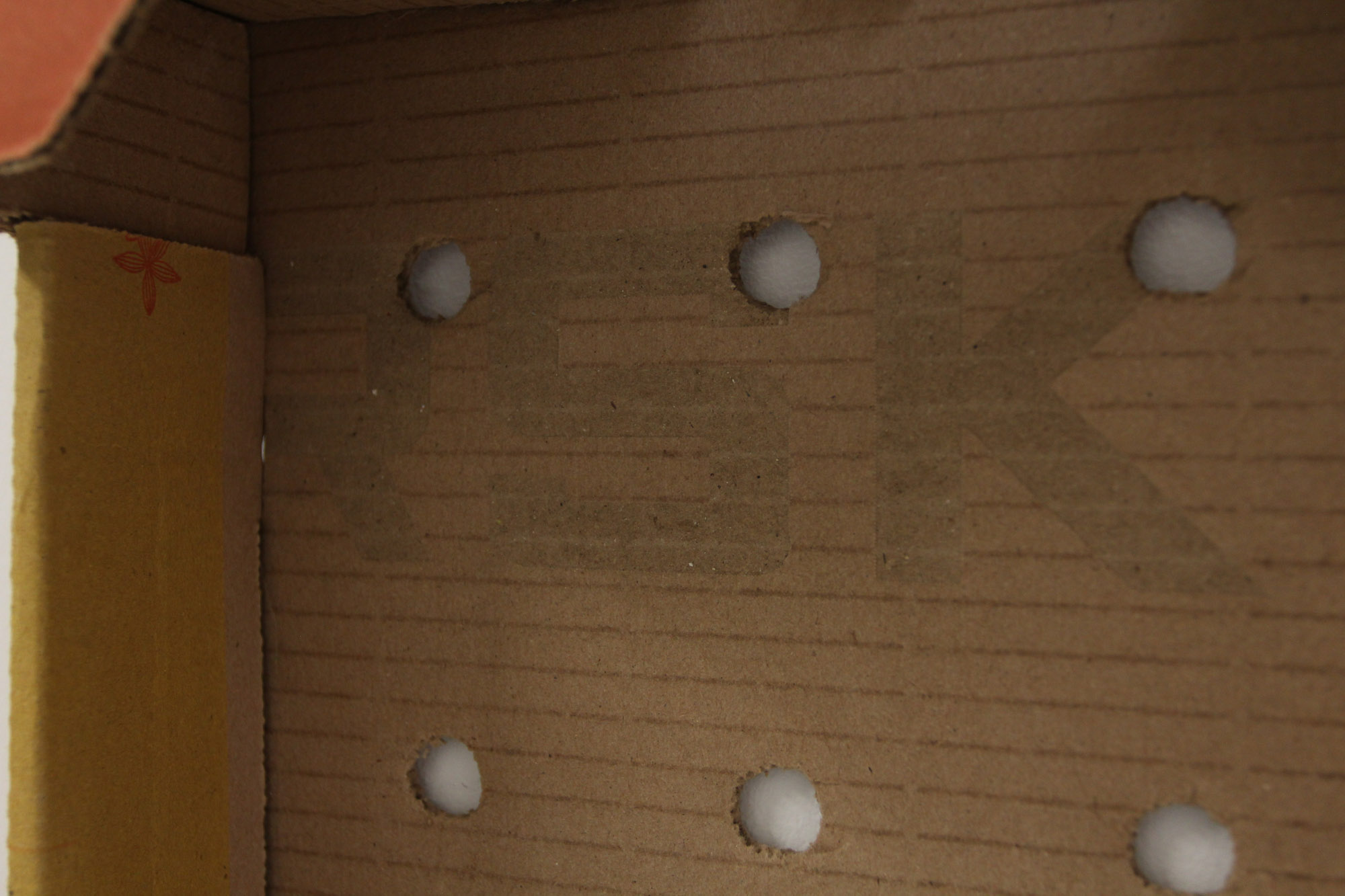

"Proud Businessman taking steps forward (MAERSK)" -

diptych - laser-etched corrugated tropical fruit trays, 2015.

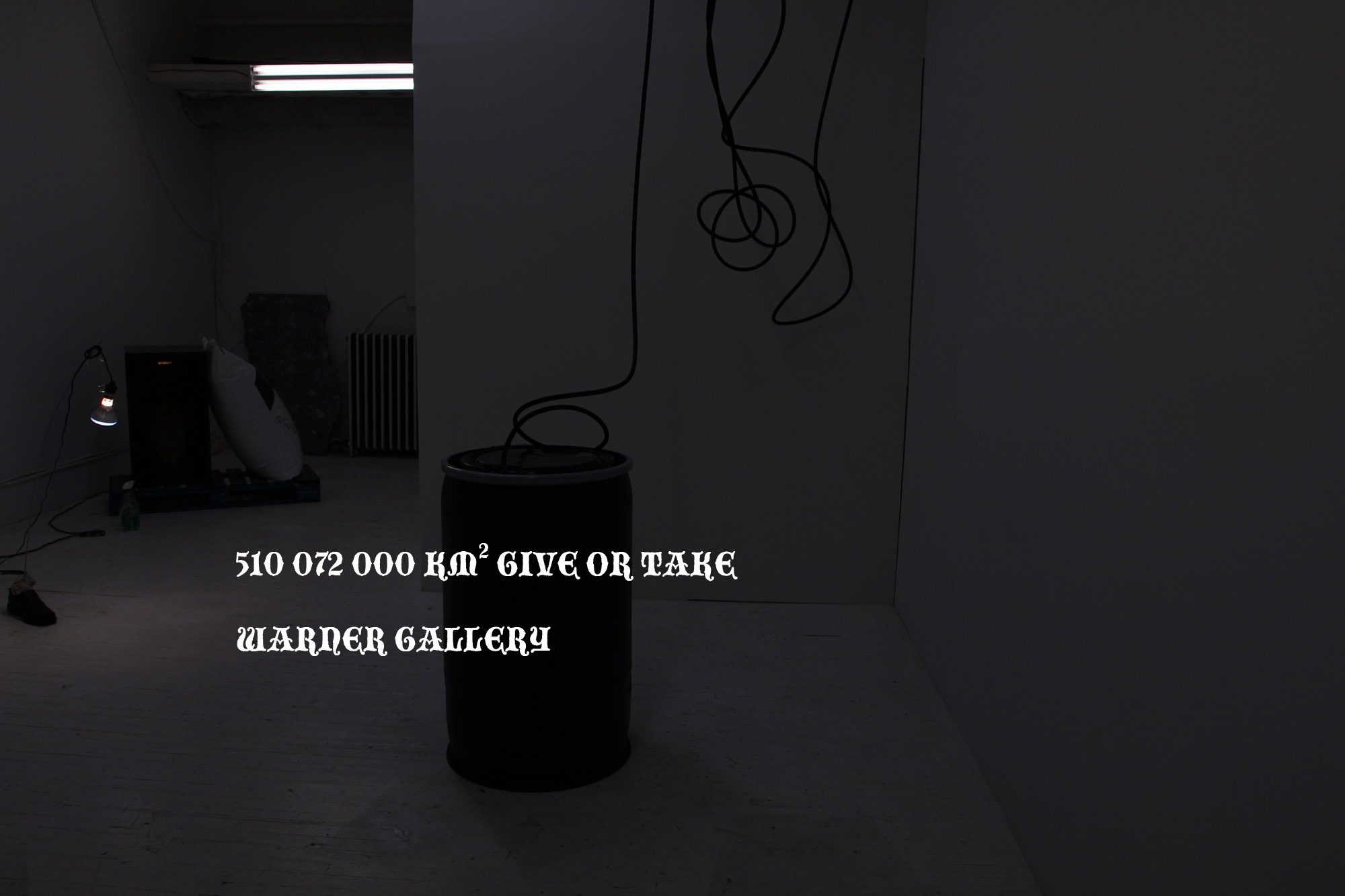

"Fully Sustainable Rainbow" -

57 gallon open top plastic drum with lockable clamp ring, soaker hose, 2015.

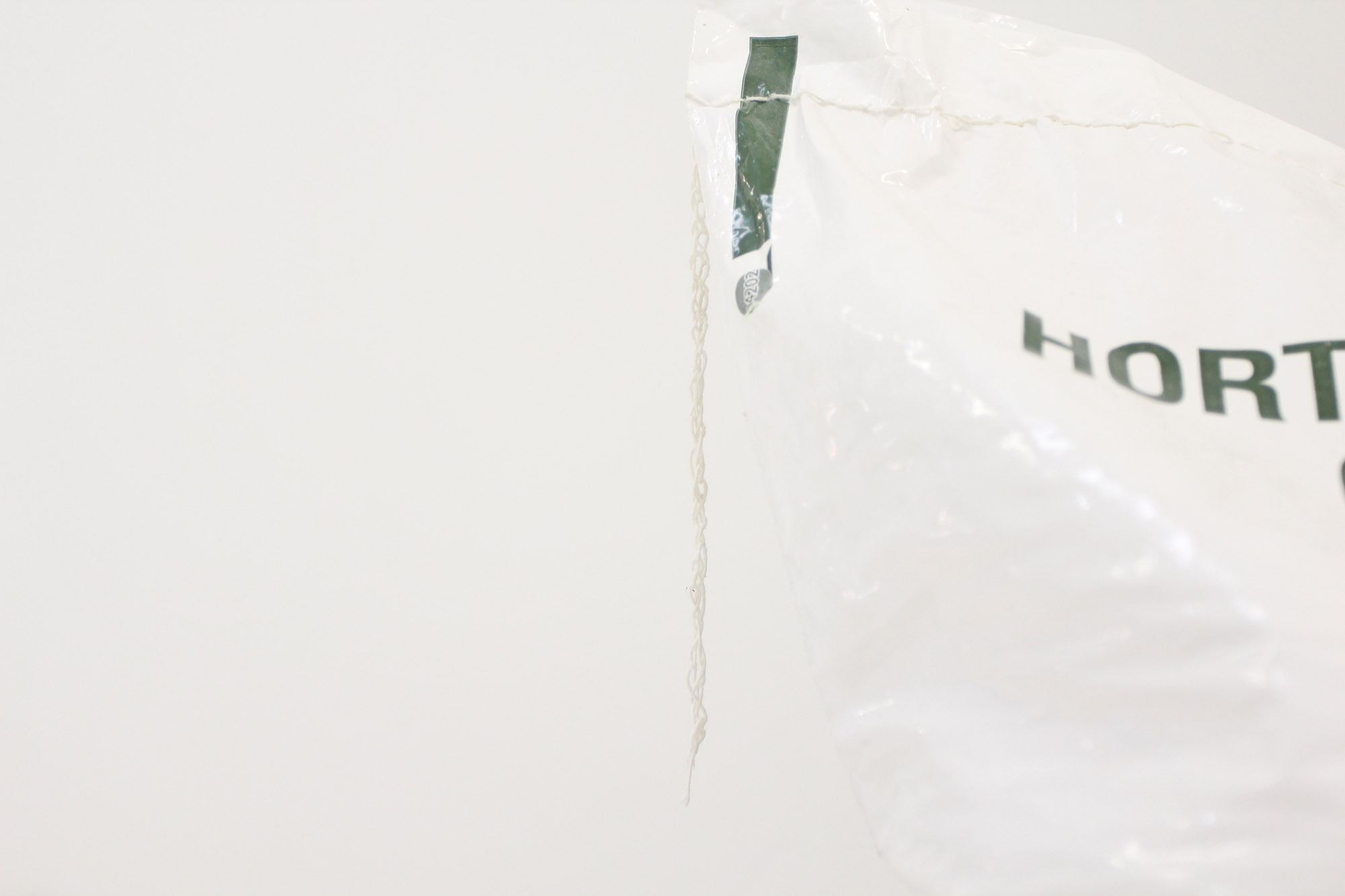

"28 commercial uses (high absorbency)" -

cardboard box, vermiculite, 2015.

In the United States, the most common pallet size is 48 inches by 40 inches. In giving the dimensions of a pallet, the first number is the length of the stringer or stringerboard, which is perpendicular to the deckboards, whose length is the second number given. Pallets may be either 4-way, meaning a forklift can lift them from any side, or 2-way, in which case two sides of the pallet are solid and the tines can only be inserted from two sides.

The world is moving toward adoption of the Euro pallet system. The standard Euro pallet (ISO 1) is 800 millimeters by 1200 millimeters.

It is usually grown locally (within 100 miles of the target market)[6] to minimize both the cost of transport and also the risk of damage to the product. The farms that produce this grass may have many varieties of grass grown in one location to best suit the consumer's use and preference of appearance.

It is usually harvested 10 to 18 months after planting, depending on the growing climate. On the farm it undergoes fertilization, frequent watering, frequent mowing and subsequent vacuuming to remove the clippings. It is harvested using specialized equipment, precision cut to standardized sizes. Sod is typically harvested in small square slabs, rolled rectangles, or large 4-foot-wide (1.2 m) rolls.

Mississippi State University has developed a hydroponic method of cultivating sod. For the very few sod farms that export turf internationally, this soil-less sod may travel both lighter and better than does traditional sod when shipped. Additionally, since the sod is not grown in soil, it doesn't need to be washed clean of soil down to the bare roots (or sprigs), and time to export is shortened.